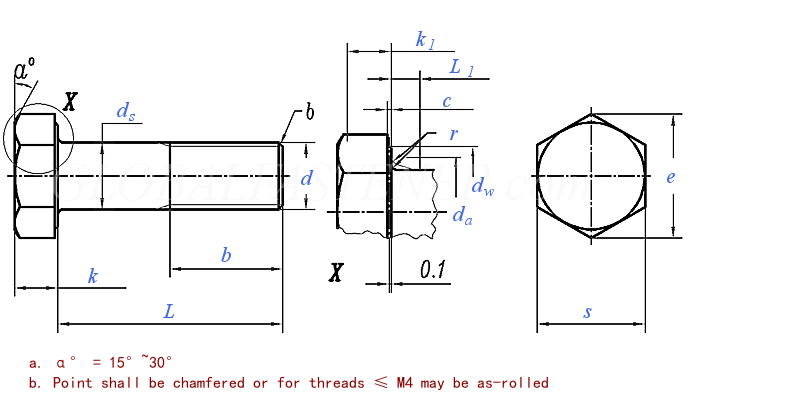

Hex Bolt Din 931 / iso4014 933 / iso4017 Grade4.8

| Sunan samfuran | HEX BOLT DIN 931/ISO4014 rabin zaren |

| Daidaitawa | DIN,ASTM/ANSI JIS EN ISO,AS,GB |

| Daraja | Girman Karfe: DIN: Gr.4.6,4.8,5.6,5.8,8.8,10.9,12.9; SAE: Gr.2,5,8; ASTM: 307A, A325, A490, |

| Ƙarshe | Zinc (Yellow, White, Blue, Black), Hop Dip Galvanized (HDG), Black Oxide, Geomet, Dacroment, anodization, Nickel plated, Zinc-Nickel plated |

| Tsarin samarwa | M2-M24: Cold Froging, M24-M100 Hot Forging, Machining da CNC don Maɓalli na Musamman |

| Lokacin Jagorar Samfuran Musamman | 30-60 kwanaki, |

| Zaren dunƙulewa | M1.6 | M2 | M2.5 | M3 | (M3.5) | M4 | M5 | M6 | (M7) | M8 | M10 | M12 | ||

| P | Fita | 0.35 | 0.4 | 0.45 | 0.5 | 0.6 | 0.7 | 0.8 | 1 | 1 | 1.25 | 1.5 | 1.75 | |

| b | L≤125 | 9 | 10 | 11 | 12 | 13 | 14 | 16 | 18 | 20 | 22 | 26 | 30 | |

| 125 ml≤200 | 15 | 16 | 17 | 18 | 19 | 20 | 22 | 24 | 26 | 28 | 32 | 36 | ||

| L >200 | 28 | 29 | 30 | 31 | 32 | 33 | 35 | 37 | 39 | 41 | 45 | 49 | ||

| c | max | 0.25 | 0.25 | 0.25 | 0.4 | 0.4 | 0.4 | 0.5 | 0.5 | 0.6 | 0.6 | 0.6 | 0.6 | |

| min | 0.1 | 0.1 | 0.1 | 0.15 | 0.15 | 0.15 | 0.15 | 0.15 | 0.15 | 0.15 | 0.15 | 0.15 | ||

| da | max | 2 | 2.6 | 3.1 | 3.6 | 4.1 | 4.7 | 5.7 | 6.8 | 7.8 | 9.2 | 11.2 | 13.7 | |

| ds | max= girman girman | 1.6 | 2 | 2.5 | 3 | 3.5 | 4 | 5 | 6 | 7 | 8 | 10 | 12 | |

| Darasi A | min | 1.46 | 1.86 | 2.36 | 2.86 | 3.32 | 3.82 | 4.82 | 5.82 | 6.78 | 7.78 | 9.78 | 11.73 | |

| Darasi B | min | 1.35 | 1.75 | 2.25 | 2.75 | 3.2 | 3.7 | 4.7 | 5.7 | 6.64 | 7.64 | 9.64 | 11.57 | |

| dw | Darasi A | min | 2.54 | 3.34 | 4.34 | 4.84 | 5.34 | 6.2 | 7.2 | 8.88 | 9.63 | 11.63 | 14.63 | 16.63 |

| Darasi B | min | 2.42 | 3.22 | 4.22 | 4.72 | 5.22 | 6.06 | 7.06 | 8.74 | 9.47 | 11.47 | 14.47 | 16.47 | |

| e | Darasi A | min | 3.41 | 4.32 | 5.45 | 6.01 | 6.58 | 7.66 | 8.79 | 11.05 | 12.12 | 14.38 | 17.77 | 20.03 |

| Darasi B | min | 3.28 | 4.18 | 5.31 | 5.88 | 6.44 | 7.5 | 8.63 | 10.89 | 11.94 | 14.2 | 17.59 | 19.85 | |

| L1 | max | 0.6 | 0.8 | 1 | 1 | 1 | 1.2 | 1.2 | 1.4 | 1.4 | 2 | 2 | 3 | |

| k | Girman Suna | 1.1 | 1.4 | 1.7 | 2 | 2.4 | 2.8 | 3.5 | 4 | 4.8 | 5.3 | 6.4 | 7.5 | |

| Darasi A | max | 1.225 | 1.525 | 1.825 | 2.125 | 2.525 | 2.925 | 3.65 | 4.15 | 4.95 | 5.45 | 6.58 | 7.68 | |

| min | 0.975 | 1.275 | 1.575 | 1.875 | 2.275 | 2.675 | 3.35 | 3.85 | 4.65 | 5.15 | 6.22 | 7.32 | ||

| Darasi B | max | 1.3 | 1.6 | 1.9 | 2.2 | 2.6 | 3 | 3.74 | 4.24 | 5.04 | 5.54 | 6.69 | 7.79 | |

| min | 0.9 | 1.2 | 1.5 | 1.8 | 2.2 | 2.6 | 3.26 | 3.76 | 4.56 | 5.06 | 6.11 | 7.21 | ||

| k1 | Darasi A | min | 0.68 | 0.89 | 1.1 | 1.31 | 1.59 | 1.87 | 2.35 | 2.7 | 3.26 | 3.61 | 4.35 | 5.12 |

| Darasi B | min | 0.63 | 0.84 | 1.05 | 1.26 | 1.54 | 1.82 | 2.28 | 2.63 | 3.19 | 3.54 | 4.28 | 5.05 | |

| r | min | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.2 | 0.2 | 0.25 | 0.25 | 0.4 | 0.4 | 0.6 | |

| s | max= girman girman | 3.2 | 4 | 5 | 5.5 | 6 | 7 | 8 | 10 | 11 | 13 | 16 | 18 | |

| Darasi A | min | 3.02 | 3.82 | 4.82 | 5.32 | 5.82 | 6.78 | 7.78 | 9.78 | 10.73 | 12.73 | 15.73 | 17.73 | |

| Darasi B | min | 2.9 | 3.7 | 4.7 | 5.2 | 5.7 | 6.64 | 7.64 | 9.64 | 10.57 | 12.57 | 15.57 | 17.57 | |

| Tsawon Zaren b | - | - | - | - | - | - | - | - | - | - | - | - | ||

| Zaren dunƙulewa | (M14) | M16 | (M18) | M20 | (M22) | M24 | (M27) | M30 | (M33) | M36 | (M39) | M42 | ||

| P | Fita | 2 | 2 | 2.5 | 2.5 | 2.5 | 3 | 3 | 3.5 | 3.5 | 4 | 4 | 4.5 | |

| b | L≤125 | 34 | 38 | 42 | 46 | 50 | 54 | 60 | 66 | 72 | - | - | - | |

| 125 ml≤200 | 40 | 44 | 48 | 52 | 56 | 60 | 66 | 72 | 78 | 84 | 90 | 96 | ||

| L >200 | 53 | 57 | 61 | 65 | 69 | 73 | 79 | 85 | 91 | 97 | 103 | 109 | ||

| c | max | 0.6 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 1 | 1 | |

| min | 0.15 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.3 | 0.3 | ||

| da | max | 15.7 | 17.7 | 20.2 | 22.4 | 24.4 | 26.4 | 30.4 | 33.4 | 36.4 | 39.4 | 42.4 | 45.6 | |

| ds | max= girman girman | 14 | 16 | 18 | 20 | 22 | 24 | 27 | 30 | 33 | 36 | 39 | 42 | |

| Darasi A | min | 13.73 | 15.73 | 17.73 | 19.67 | 21.67 | 23.67 | - | - | - | - | - | - | |

| Darasi B | min | 13.57 | 15.57 | 17.57 | 19.48 | 21.48 | 23.48 | 26.48 | 29.48 | 32.38 | 35.38 | 38.38 | 41.38 | |

| dw | Darasi A | min | 19.64 | 22.49 | 25.34 | 28.19 | 31.71 | 33.61 | - | - | - | - | - | - |

| Darasi B | min | 19.15 | 22 | 24.85 | 27.7 | 31.35 | 33.25 | 38 | 42.75 | 46.55 | 51.11 | 55.86 | 59.95 | |

| e | Darasi A | min | 23.36 | 26.75 | 30.14 | 33.53 | 37.72 | 39.98 | - | - | - | - | - | - |

| Darasi B | min | 22.78 | 26.17 | 29.56 | 32.95 | 37.29 | 39.55 | 45.2 | 50.85 | 55.37 | 60.79 | 66.44 | 71.3 | |

| L1 | max | 3 | 3 | 3 | 4 | 4 | 4 | 6 | 6 | 6 | 6 | 6 | 8 | |

| k | Girman Suna | 8.8 | 10 | 11.5 | 12.5 | 14 | 15 | 17 | 18.7 | 21 | 22.5 | 25 | 26 | |

| Darasi A | max | 8.98 | 10.18 | 11.715 | 12.715 | 14.215 | 15.215 | - | - | - | - | - | - | |

| min | 8.62 | 9.82 | 11.285 | 12.285 | 13.785 | 14.785 | - | - | - | - | - | - | ||

| Darasi B | max | 9.09 | 10.29 | 11.85 | 12.85 | 14.35 | 15.35 | 17.35 | 19.12 | 21.42 | 22.92 | 25.42 | 26.42 | |

| min | 8.51 | 9.71 | 11.15 | 12.15 | 13.65 | 14.65 | 16.65 | 18.28 | 20.58 | 22.08 | 24.58 | 25.58 | ||

| k1 | Darasi A | min | 6.03 | 6.87 | 7.9 | 8.6 | 9.65 | 10.35 | - | - | - | - | - | - |

| Darasi B | min | 5.96 | 6.8 | 7.81 | 8.51 | 9.56 | 10.26 | 11.66 | 12.8 | 14.41 | 15.46 | 17.21 | 17.91 | |

| r | min | 0.6 | 0.6 | 0.6 | 0.8 | 0.8 | 0.8 | 1 | 1 | 1 | 1 | 1 | 1.2 | |

| s | max= girman girman | 21 | 24 | 27 | 30 | 34 | 36 | 41 | 46 | 50 | 55 | 60 | 65 | |

| Darasi A | min | 20.67 | 23.67 | 26.67 | 29.67 | 33.38 | 35.38 | - | - | - | - | - | - | |

| Darasi B | min | 20.16 | 23.16 | 26.16 | 29.16 | 33 | 35 | 40 | 45 | 49 | 53.8 | 58.8 | 63.1 | |

| Tsawon Zaren b | - | - | - | - | - | - | - | - | - | - |

|

| ||

| Zaren dunƙulewa | (M45) | M48 | (M52) | M56 | (M60) | M64 |

|

|

|

|

|

| ||

| P | Fita | 4.5 | 5 | 5 | 5.5 | 5.5 | 6 |

|

|

|

|

|

| |

| b | L≤125 | - | - | - | - | - | - |

|

|

|

|

|

| |

| 125 ml≤200 | 102 | 108 | 116 | - | - | - |

|

|

|

|

|

| ||

| L >200 | 115 | 121 | 129 | 137 | 145 | 153 |

|

|

|

|

|

| ||

| c | max | 1 | 1 | 1 | 1 | 1 | 1 |

|

|

|

|

|

| |

| min | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 |

|

|

|

|

|

| ||

| da | max | 48.6 | 52.6 | 56.6 | 63 | 67 | 71 |

|

|

|

|

|

| |

| ds | max= girman girman | 45 | 48 | 52 | 56 | 60 | 64 |

|

|

|

|

|

| |

| Darasi A | min | - | - | - | - | - | - |

|

|

|

|

|

| |

| Darasi B | min | 44.38 | 47.38 | 51.26 | 55.26 | 59.26 | 63.26 |

|

|

|

|

|

| |

| dw | Darasi A | min | - | - | - | - | - | - |

|

|

|

|

|

|

| Darasi B | min | 64.7 | 69.45 | 74.2 | 78.66 | 83.41 | 88.16 |

|

|

|

|

|

| |

| e | Darasi A | min | - | - | - | - | - | - |

|

|

|

|

|

|

| Darasi B | min | 76.95 | 82.6 | 88.25 | 93.56 | 99.21 | 104.86 |

|

|

|

|

|

| |

| L1 | max | 8 | 10 | 10 | 12 | 12 | 13 |

|

|

|

|

|

| |

| k | Girman Suna | 28 | 30 | 33 | 35 | 38 | 40 |

|

|

|

|

|

| |

| Darasi A | max | - | - | - | - | - | - |

|

|

|

|

|

| |

| min | - | - | - | - | - | - |

|

|

|

|

|

| ||

| Darasi B | max | 28.42 | 30.42 | 33.5 | 35.5 | 38.5 | 40.5 |

|

|

|

|

|

| |

| min | 27.58 | 29.58 | 32.5 | 34.5 | 37.5 | 39.5 |

|

|

|

|

|

| ||

| k1 | Darasi A | min | - | - | - | - | - | - |

|

|

|

|

|

|

| Darasi B | min | 19.31 | 20.71 | 22.75 | 24.15 | 26.25 | 27.65 |

|

|

|

|

|

| |

| r | min | 1.2 | 1.6 | 1.6 | 2 | 2 | 2 |

|

|

|

|

|

| |

| s | max= girman girman | 70 | 75 | 80 | 85 | 90 | 95 |

|

|

|

|

|

| |

| Darasi A | min | - | - | - | - | - | - |

|

|

|

|

|

| |

| Darasi B | min | 68.1 | 73.1 | 78.1 | 82.8 | 87.8 | 92.8 |

|

|

|

|

|

| |

| Tsawon Zaren b | - | - | - | - | - | - |

|

|

|

|

| |||

Features da Fa'idodi

A cikin duniyar kayan ɗamara, Hex Bolt Din 931, ISO4014 933, da ISO4017 Grade 4.8 sune wasu samfuran da aka fi nema. Wadannan hex bolts sune ginshiƙai a cikin gine-gine da masana'antu yayin da suke ba da kyakkyawan kwanciyar hankali, dorewa kuma suna iya jure babban matsa lamba da tashin hankali.

Hex Bolt Din 931, ISO4014 933, da ISO4017 Grade 4.8 suna samuwa a cikin kewayon masu girma dabam don dacewa da aikace-aikace daban-daban. Wadannan kusoshi an yi su ne da ƙarfe na carbon tare da ƙarewar farantin, yana tabbatar da tsatsa da juriya. An ƙera su da kawuna masu gefe shida don samar da tabbataccen riko don kayan aiki kamar maƙarƙashiya ko manne. Ana amfani da bolts na hex don haɗa abubuwa biyu ko fiye tare, yana mai da su dacewa ga masana'antu daban-daban kamar na motoci, sararin samaniya, gini da noma.

Ɗaya daga cikin mahimman fa'idodin amfani da waɗannan bolts hex shine ƙarfin su da dorewa. Wadannan kusoshi na iya jure wa babban matsin lamba da tashin hankali, yana mai da su manufa don amintaccen kayan aikin inji da injina. Bugu da ƙari, taurin ƙullun yana tabbatar da cewa ba su da lahani ga nakasu ko murdiya lokacin da aka yi musu na waje.

Hex Bolt Din 931, ISO4014 933, da ISO4017 Grade 4.8 suna ba da kyakkyawan aiki a cikin yanayi mara kyau. Bugu da ƙari ga platin su na jure lalata, za su iya jure yanayin zafi, sanyi, da danshi. Wannan yana da mahimmanci a cikin saitunan masana'antu inda matsanancin yanayin zafi, sunadarai, da ruwa zasu iya haifar da lalacewa ga masu ɗaure, kuma, bi da bi, lalata amincin tsarin gaba ɗaya.

Za'a iya amfani da bolts na hex a cikin nau'i daban-daban dangane da takamaiman masana'antu ko buƙatun. Wasu suna amfani da su da wanki da na goro don ƙarin tsaro yayin da wasu ke amfani da su da anka ko dunƙule matosai don kiyaye abubuwa zuwa bango da rufi. Ko da yaya ake amfani da su, Hex Bolt Din 931, ISO4014 933, da ISO4017 Grade 4.8 suna taka muhimmiyar rawa wajen kiyaye tsarin da ayyuka daban-daban tare.

A ƙarshe, hex bolts sune madaidaicin masana'antu daban-daban a duniya, kuma suna ci gaba da ba da aiki na musamman da aminci. Hex Bolt Din 931, ISO4014 933, da ISO4017 Grade 4.8 ba banda bane, kuma suna ba da ƙimar kuɗi mai kyau. Wadannan kusoshi sune kashin bayan tsarin da yawa, kuma ba za a iya rage mahimmancin su ba.