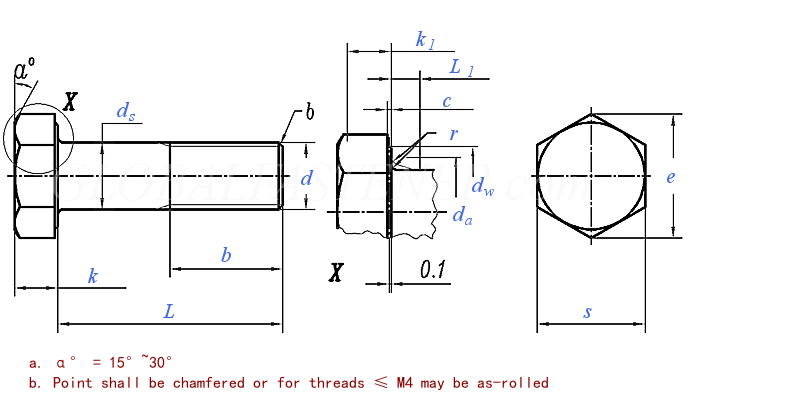

Hexagon Bolts an ƙirƙira su zuwa DIN 931

| Sunan samfuran | HEX BOLT DIN 931/ISO4014 rabin zaren |

| Daidaitawa | DIN,ASTM/ANSI JIS EN ISO,AS,GB |

| Daraja | Girman Karfe: DIN: Gr.4.6,4.8,5.6,5.8,8.8,10.9,12.9; SAE: Gr.2,5,8; ASTM: 307A, A325, A490, |

| Ƙarshe | Zinc (Yellow, White, Blue, Black), Hop Dip Galvanized (HDG), Black Oxide, Geomet, Dacroment, anodization, Nickel plated, Zinc-Nickel plated |

| Tsarin samarwa | M2-M24: Cold Froging, M24-M100 Hot Forging, Machining da CNC don Maɓalli na Musamman |

| Lokacin Jagorar Samfuran Musamman | 30-60 kwanaki, |

| Zaren dunƙulewa | M1.6 | M2 | M2.5 | M3 | (M3.5) | M4 | M5 | M6 | (M7) | M8 | M10 | M12 | ||

| P | Fita | 0.35 | 0.4 | 0.45 | 0.5 | 0.6 | 0.7 | 0.8 | 1 | 1 | 1.25 | 1.5 | 1.75 | |

| b | L≤125 | 9 | 10 | 11 | 12 | 13 | 14 | 16 | 18 | 20 | 22 | 26 | 30 | |

| 125 ml≤200 | 15 | 16 | 17 | 18 | 19 | 20 | 22 | 24 | 26 | 28 | 32 | 36 | ||

| L >200 | 28 | 29 | 30 | 31 | 32 | 33 | 35 | 37 | 39 | 41 | 45 | 49 | ||

| c | max | 0.25 | 0.25 | 0.25 | 0.4 | 0.4 | 0.4 | 0.5 | 0.5 | 0.6 | 0.6 | 0.6 | 0.6 | |

| min | 0.1 | 0.1 | 0.1 | 0.15 | 0.15 | 0.15 | 0.15 | 0.15 | 0.15 | 0.15 | 0.15 | 0.15 | ||

| da | max | 2 | 2.6 | 3.1 | 3.6 | 4.1 | 4.7 | 5.7 | 6.8 | 7.8 | 9.2 | 11.2 | 13.7 | |

| ds | max= girman girman | 1.6 | 2 | 2.5 | 3 | 3.5 | 4 | 5 | 6 | 7 | 8 | 10 | 12 | |

| Darasi A | min | 1.46 | 1.86 | 2.36 | 2.86 | 3.32 | 3.82 | 4.82 | 5.82 | 6.78 | 7.78 | 9.78 | 11.73 | |

| Darasi B | min | 1.35 | 1.75 | 2.25 | 2.75 | 3.2 | 3.7 | 4.7 | 5.7 | 6.64 | 7.64 | 9.64 | 11.57 | |

| dw | Darasi A | min | 2.54 | 3.34 | 4.34 | 4.84 | 5.34 | 6.2 | 7.2 | 8.88 | 9.63 | 11.63 | 14.63 | 16.63 |

| Darasi B | min | 2.42 | 3.22 | 4.22 | 4.72 | 5.22 | 6.06 | 7.06 | 8.74 | 9.47 | 11.47 | 14.47 | 16.47 | |

| e | Darasi A | min | 3.41 | 4.32 | 5.45 | 6.01 | 6.58 | 7.66 | 8.79 | 11.05 | 12.12 | 14.38 | 17.77 | 20.03 |

| Darasi B | min | 3.28 | 4.18 | 5.31 | 5.88 | 6.44 | 7.5 | 8.63 | 10.89 | 11.94 | 14.2 | 17.59 | 19.85 | |

| L1 | max | 0.6 | 0.8 | 1 | 1 | 1 | 1.2 | 1.2 | 1.4 | 1.4 | 2 | 2 | 3 | |

| k | Girman Suna | 1.1 | 1.4 | 1.7 | 2 | 2.4 | 2.8 | 3.5 | 4 | 4.8 | 5.3 | 6.4 | 7.5 | |

| Darasi A | max | 1.225 | 1.525 | 1.825 | 2.125 | 2.525 | 2.925 | 3.65 | 4.15 | 4.95 | 5.45 | 6.58 | 7.68 | |

| min | 0.975 | 1.275 | 1.575 | 1.875 | 2.275 | 2.675 | 3.35 | 3.85 | 4.65 | 5.15 | 6.22 | 7.32 | ||

| Darasi B | max | 1.3 | 1.6 | 1.9 | 2.2 | 2.6 | 3 | 3.74 | 4.24 | 5.04 | 5.54 | 6.69 | 7.79 | |

| min | 0.9 | 1.2 | 1.5 | 1.8 | 2.2 | 2.6 | 3.26 | 3.76 | 4.56 | 5.06 | 6.11 | 7.21 | ||

| k1 | Darasi A | min | 0.68 | 0.89 | 1.1 | 1.31 | 1.59 | 1.87 | 2.35 | 2.7 | 3.26 | 3.61 | 4.35 | 5.12 |

| Darasi B | min | 0.63 | 0.84 | 1.05 | 1.26 | 1.54 | 1.82 | 2.28 | 2.63 | 3.19 | 3.54 | 4.28 | 5.05 | |

| r | min | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.2 | 0.2 | 0.25 | 0.25 | 0.4 | 0.4 | 0.6 | |

| s | max= girman girman | 3.2 | 4 | 5 | 5.5 | 6 | 7 | 8 | 10 | 11 | 13 | 16 | 18 | |

| Darasi A | min | 3.02 | 3.82 | 4.82 | 5.32 | 5.82 | 6.78 | 7.78 | 9.78 | 10.73 | 12.73 | 15.73 | 17.73 | |

| Darasi B | min | 2.9 | 3.7 | 4.7 | 5.2 | 5.7 | 6.64 | 7.64 | 9.64 | 10.57 | 12.57 | 15.57 | 17.57 | |

| Tsawon Zaren b | - | - | - | - | - | - | - | - | - | - | - | - | ||

| Zaren dunƙulewa | (M14) | M16 | (M18) | M20 | (M22) | M24 | (M27) | M30 | (M33) | M36 | (M39) | M42 | ||

| P | Fita | 2 | 2 | 2.5 | 2.5 | 2.5 | 3 | 3 | 3.5 | 3.5 | 4 | 4 | 4.5 | |

| b | L≤125 | 34 | 38 | 42 | 46 | 50 | 54 | 60 | 66 | 72 | - | - | - | |

| 125 ml≤200 | 40 | 44 | 48 | 52 | 56 | 60 | 66 | 72 | 78 | 84 | 90 | 96 | ||

| L >200 | 53 | 57 | 61 | 65 | 69 | 73 | 79 | 85 | 91 | 97 | 103 | 109 | ||

| c | max | 0.6 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 1 | 1 | |

| min | 0.15 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.3 | 0.3 | ||

| da | max | 15.7 | 17.7 | 20.2 | 22.4 | 24.4 | 26.4 | 30.4 | 33.4 | 36.4 | 39.4 | 42.4 | 45.6 | |

| ds | max= girman girman | 14 | 16 | 18 | 20 | 22 | 24 | 27 | 30 | 33 | 36 | 39 | 42 | |

| Darasi A | min | 13.73 | 15.73 | 17.73 | 19.67 | 21.67 | 23.67 | - | - | - | - | - | - | |

| Darasi B | min | 13.57 | 15.57 | 17.57 | 19.48 | 21.48 | 23.48 | 26.48 | 29.48 | 32.38 | 35.38 | 38.38 | 41.38 | |

| dw | Darasi A | min | 19.64 | 22.49 | 25.34 | 28.19 | 31.71 | 33.61 | - | - | - | - | - | - |

| Darasi B | min | 19.15 | 22 | 24.85 | 27.7 | 31.35 | 33.25 | 38 | 42.75 | 46.55 | 51.11 | 55.86 | 59.95 | |

| e | Darasi A | min | 23.36 | 26.75 | 30.14 | 33.53 | 37.72 | 39.98 | - | - | - | - | - | - |

| Darasi B | min | 22.78 | 26.17 | 29.56 | 32.95 | 37.29 | 39.55 | 45.2 | 50.85 | 55.37 | 60.79 | 66.44 | 71.3 | |

| L1 | max | 3 | 3 | 3 | 4 | 4 | 4 | 6 | 6 | 6 | 6 | 6 | 8 | |

| k | Girman Suna | 8.8 | 10 | 11.5 | 12.5 | 14 | 15 | 17 | 18.7 | 21 | 22.5 | 25 | 26 | |

| Darasi A | max | 8.98 | 10.18 | 11.715 | 12.715 | 14.215 | 15.215 | - | - | - | - | - | - | |

| min | 8.62 | 9.82 | 11.285 | 12.285 | 13.785 | 14.785 | - | - | - | - | - | - | ||

| Darasi B | max | 9.09 | 10.29 | 11.85 | 12.85 | 14.35 | 15.35 | 17.35 | 19.12 | 21.42 | 22.92 | 25.42 | 26.42 | |

| min | 8.51 | 9.71 | 11.15 | 12.15 | 13.65 | 14.65 | 16.65 | 18.28 | 20.58 | 22.08 | 24.58 | 25.58 | ||

| k1 | Darasi A | min | 6.03 | 6.87 | 7.9 | 8.6 | 9.65 | 10.35 | - | - | - | - | - | - |

| Darasi B | min | 5.96 | 6.8 | 7.81 | 8.51 | 9.56 | 10.26 | 11.66 | 12.8 | 14.41 | 15.46 | 17.21 | 17.91 | |

| r | min | 0.6 | 0.6 | 0.6 | 0.8 | 0.8 | 0.8 | 1 | 1 | 1 | 1 | 1 | 1.2 | |

| s | max= girman girman | 21 | 24 | 27 | 30 | 34 | 36 | 41 | 46 | 50 | 55 | 60 | 65 | |

| Darasi A | min | 20.67 | 23.67 | 26.67 | 29.67 | 33.38 | 35.38 | - | - | - | - | - | - | |

| Darasi B | min | 20.16 | 23.16 | 26.16 | 29.16 | 33 | 35 | 40 | 45 | 49 | 53.8 | 58.8 | 63.1 | |

| Tsawon Zaren b | - | - | - | - | - | - | - | - | - | - |

|

| ||

| Zaren dunƙulewa | (M45) | M48 | (M52) | M56 | (M60) | M64 |

|

|

|

|

|

| ||

| P | Fita | 4.5 | 5 | 5 | 5.5 | 5.5 | 6 |

|

|

|

|

|

| |

| b | L≤125 | - | - | - | - | - | - |

|

|

|

|

|

| |

| 125 ml≤200 | 102 | 108 | 116 | - | - | - |

|

|

|

|

|

| ||

| L >200 | 115 | 121 | 129 | 137 | 145 | 153 |

|

|

|

|

|

| ||

| c | max | 1 | 1 | 1 | 1 | 1 | 1 |

|

|

|

|

|

| |

| min | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 |

|

|

|

|

|

| ||

| da | max | 48.6 | 52.6 | 56.6 | 63 | 67 | 71 |

|

|

|

|

|

| |

| ds | max= girman girman | 45 | 48 | 52 | 56 | 60 | 64 |

|

|

|

|

|

| |

| Darasi A | min | - | - | - | - | - | - |

|

|

|

|

|

| |

| Darasi B | min | 44.38 | 47.38 | 51.26 | 55.26 | 59.26 | 63.26 |

|

|

|

|

|

| |

| dw | Darasi A | min | - | - | - | - | - | - |

|

|

|

|

|

|

| Darasi B | min | 64.7 | 69.45 | 74.2 | 78.66 | 83.41 | 88.16 |

|

|

|

|

|

| |

| e | Darasi A | min | - | - | - | - | - | - |

|

|

|

|

|

|

| Darasi B | min | 76.95 | 82.6 | 88.25 | 93.56 | 99.21 | 104.86 |

|

|

|

|

|

| |

| L1 | max | 8 | 10 | 10 | 12 | 12 | 13 |

|

|

|

|

|

| |

| k | Girman Suna | 28 | 30 | 33 | 35 | 38 | 40 |

|

|

|

|

|

| |

| Darasi A | max | - | - | - | - | - | - |

|

|

|

|

|

| |

| min | - | - | - | - | - | - |

|

|

|

|

|

| ||

| Darasi B | max | 28.42 | 30.42 | 33.5 | 35.5 | 38.5 | 40.5 |

|

|

|

|

|

| |

| min | 27.58 | 29.58 | 32.5 | 34.5 | 37.5 | 39.5 |

|

|

|

|

|

| ||

| k1 | Darasi A | min | - | - | - | - | - | - |

|

|

|

|

|

|

| Darasi B | min | 19.31 | 20.71 | 22.75 | 24.15 | 26.25 | 27.65 |

|

|

|

|

|

| |

| r | min | 1.2 | 1.6 | 1.6 | 2 | 2 | 2 |

|

|

|

|

|

| |

| s | max= girman girman | 70 | 75 | 80 | 85 | 90 | 95 |

|

|

|

|

|

| |

| Darasi A | min | - | - | - | - | - | - |

|

|

|

|

|

| |

| Darasi B | min | 68.1 | 73.1 | 78.1 | 82.8 | 87.8 | 92.8 |

|

|

|

|

|

| |

| Tsawon Zaren b | - | - | - | - | - | - |

|

|

|

|

| |||

Features da Fa'idodi

Kullun hexagon nau'i ne na maɗauri wanda aka ƙera tare da kai mai gefe shida da ramin zare. DIN 931 daidaitaccen ma'aunin fasaha ne wanda ke fayyace buƙatun masana'anta don kusoshi hexagon. Ana amfani da waɗannan kusoshi a cikin aikace-aikacen masana'antu da injiniyoyi daban-daban saboda ƙarfinsu, ƙarfinsu, da ƙarfinsu.

Ɗaya daga cikin mahimman fasalulluka na kusoshi hexagon da aka ƙirƙira zuwa DIN 931 shine zaren ɓangaren su. Ba kamar ƙwanƙolin zaren da aka zana ba, waɗanda ke da zaren da ke tafiyar da tsayin tsayin igiyar, ƙullun hexagon kawai suna da zaren akan wani yanki na tsawonsu. Wannan ƙira yana ba da damar a ɗaure kullin amintacce a wurin yayin da har yanzu yana ba da isasshen izini don abubuwan da za su motsa idan ya cancanta.

Wani muhimmin al'amari na kusoshi hexagon shine kai mai gefe shida. Wannan zane yana ba da fa'idodi da yawa akan sauran nau'ikan kusoshi. Da fari dai, siffar hexagonal yana ba da damar ƙarfafawa da sauƙi da sassautawa tare da maƙarƙashiya ko soket. Abu na biyu, babban saman saman kai yana rarraba ƙarfin ƙarfafawa a kan wani yanki mai faɗi, yana rage yiwuwar lalacewa ko lalacewa.

Hexagon bolts da aka ƙirƙira zuwa DIN 931 suna samuwa a cikin nau'i-nau'i masu yawa da kayan aiki, suna sa su dace da aikace-aikace masu yawa. Ana amfani da su a cikin gine-gine, motoci, da injunan masana'antu, da kuma a cikin ayyukan gida da na DIY. Haɗuwa da ƙarfinsu, dorewa, da sauƙin amfani yana sanya kusoshi hexagon ya zama muhimmin sashi a cikin nau'ikan injina da kayan aiki da yawa.

A taƙaice, ƙusoshin hexagon da aka ƙirƙira zuwa DIN 931 an ƙera su don samar da amintaccen kuma abin dogaro na ɗaure don aikace-aikace iri-iri. Ramin da aka zare su da kai da kai mai gefe shida suna ba da fa'idodi iri-iri, gami da sauƙin amfani, ƙara ƙarfi da karko, da haɓakawa. Wadannan kusoshi wani muhimmin bangare ne na nau'ikan injina da kayan aiki da yawa, kuma shahararsu shaida ce ta inganci da ingancinsu.